Solution

Suspension HIL test system

With the transformation of electrification and intelligence, active suspension technology is developing rapidly. HIL testing is key before it can be applied to actual car production.

For traditional real vehicle testing, the cost is high and the cycle is long; Extreme conditions are difficult to reproduce (e.g., high-speed bumps, emergency lane changes); The control algorithm verification relies on the pain points of the real vehicle in the later stage, such as the risk lag, and the HIL test can perfectly achieve the goals of shortening the development cycle (verifying the algorithm and hardware in advance), reducing the test cost (reducing the number of road tests of the real vehicle), and improving the safety (fault injection simulation to avoid the risk of the real vehicle).

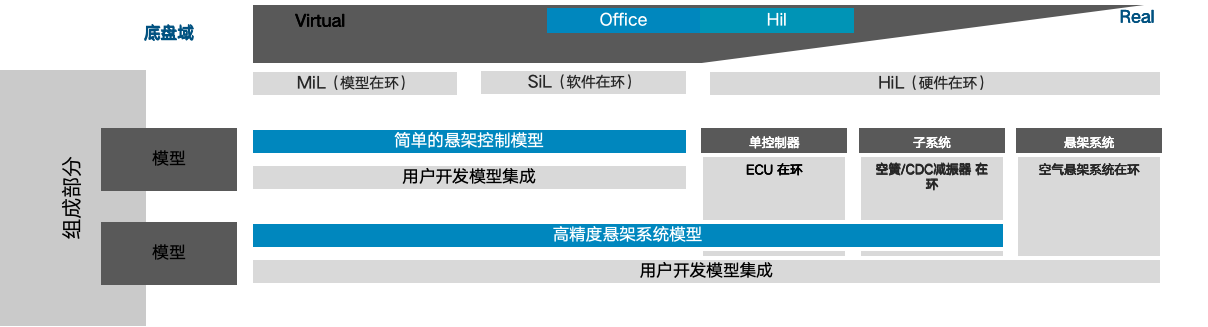

System architecture

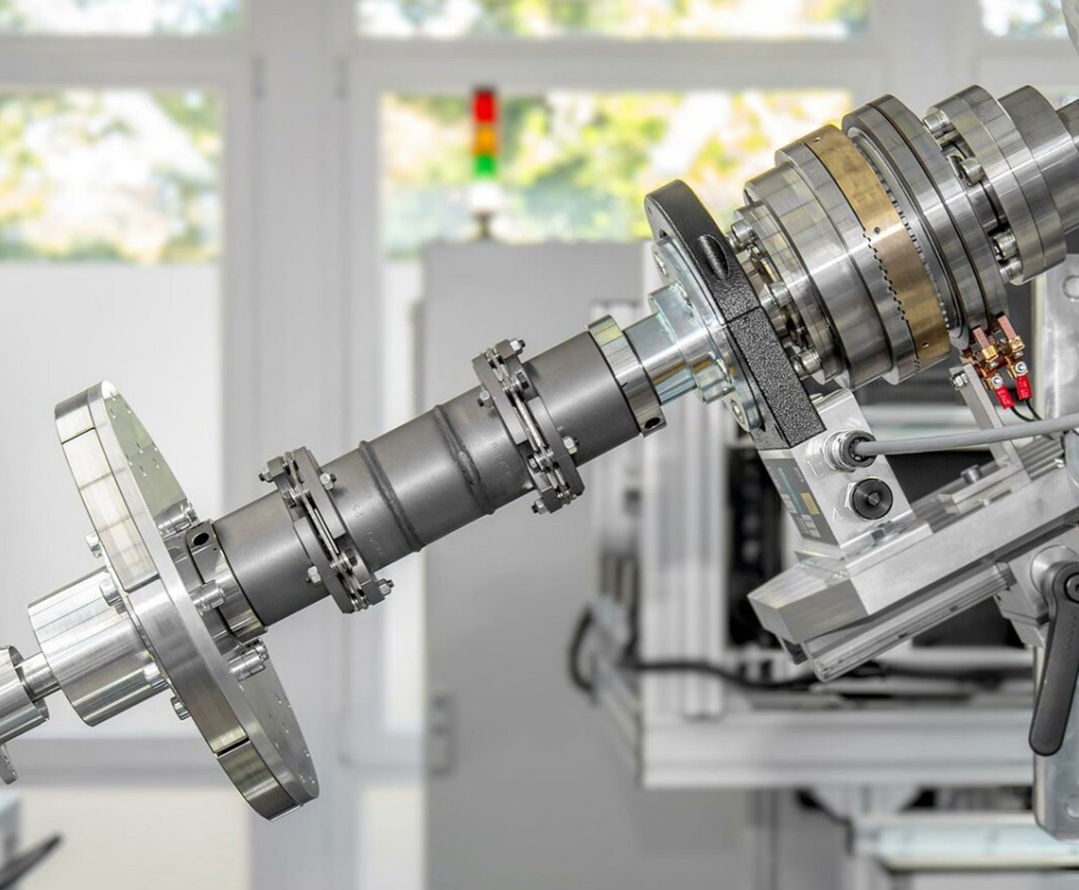

The hardware is at the ring layer

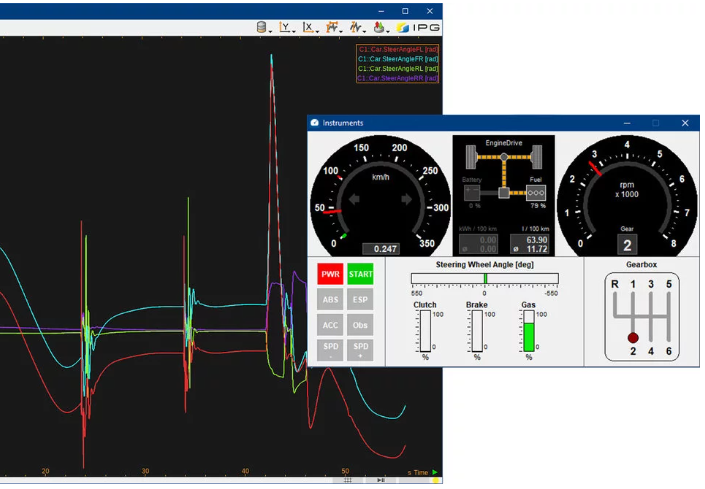

Real-time simulators (e.g., IPG, NI)

Fault injection unit

Vehicle model layer

High-precision vehicle dynamics models

Multibody dynamics model of a suspension system

Test management platform

Automated test scripts

Data collection and analysis tools

System architecture

Contact: Bay Max

Phone: 136218783885

E-mail: max@novatech-js.com

Address: Science and Technology Innovation Park, Taicang Zhihui Valley, Suzhou City, Jiangsu Province

WeChat Public Number

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

©2024 Jiangsu NOVATECH Automation Technology Co., Ltd Powered by www.300.cn SEO Privacy Policy

Online Message